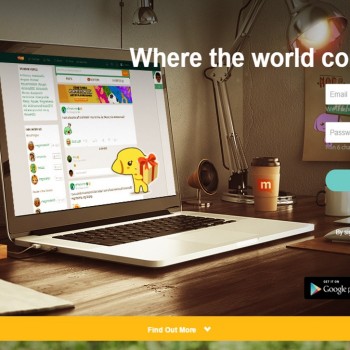

運用3D列印,Motorola的Ara計劃給予你組裝一台智慧型手機的能力

美國人每年更換1.3億台手機,而其中不到10%有得到回收。甚至有些消費者會希望自己的手機壞掉,能夠讓他們立即搶到最新的技術並且升級。

目前Motorola為Google所有,Ara計劃的目標是打造出模組化手機。而這間公司也剛跟南卡羅來納州的3D列印公司簽約,目的是創建一個生產質量可以彈性變化的模組化手機生產平台。而這些零件只需要卡進框架以及視時間點決定是否升級。

模組化智慧型手機讓消費者決定什麼元素對他們是比較重要的。如果是照相機,舉例來說,就能購買高品質的照相鏡頭並且組裝進去。如果是不同種類的顯示器,消費者同樣有機會獲得。Information Week稱其為:「樂高風格的客製化。」當然,這樣的手機將意味著一般智慧型手機的消費可能會下降,並且減少浪費的機會。

但在Ara計劃抵達消費者手中之前,發生很多問題。「在Ara計劃中,我們提出一個問題:『我們如何把這種客製化跟硬體開放系統的好處擴及到六十億人?』這驅使我們繼續努力。」

副總裁兼研發主任Regina Dugan在AllThingsD中這麼說。「他需要技術上的進步,像是元素的強度跟引刷時天線的導電油墨。這些進步必須能夠支撐生產的速度和體積,這就是我們跟3D Systems的合作關係。」

其實Motorola早前已經推出美國生產的Moto X,逐漸深入客製化手機的業務中。

Americans replace 130 million mobile phones annually, and not even 10 percent of those get recycled. Even those consumers that try to hold out from snapping up new technology immediately find themselves practically begging their phones to fall apart so they can make the upgrade in good conscience.

Google-owned Motorola is aiming to help the problem with its modular smartphone project, Project Ara. The company has just signed a deal with a South Carolina 3D printing company to create a modular phone production platform that can be scaled for mass distribution. The pieces only need to be snapped into aa frame if and when an upgrade is needed.

The modular smartphones will allow consumers to decide what elements are most important to them. If it is the camera, for example, a higher-quality camera module can be bought and snapped into place. If it is a different kind of display, the consumer will have access to that as well. Information Week calls it “Lego-style customization.” Such a phone, of course, would mean that smartphone sales in general could go down and less phones would be wasted.

But a lot has to happen before Ara ends up in consumers’ hands. “With Project Ara, we asked the question, ‘How do we bring the benefits of customization and an open hardware ecosystem to six billion people?’ That is our driving application,” Senior VP and advanced research head Regina Dugan said, according to AllThingsD. “It requires technical advances in areas such as material strength and printing with conductive inks for antennas. And those advances must support production-level speeds and volumes, which is a natural partnership with 3D Systems.”

Motorola has already gotten into the custom phone business with its made-in-the-USA Moto X smartphone that was released earlier this year.

摘譯自BrandChannel:

http://www.brandchannel.com/Posted by Mark J. Miller on November 25, 2013 05:58 PM

![[圖一] 薯條王 logo](http://www.bpaper.org.tw/wp-content/uploads/2014/04/04-2-1-01.jpg)

![[圖四] 地產大亨](http://www.bpaper.org.tw/wp-content/uploads/2014/04/04-2-4-01.jpg)